Hyundai Mobis: Achieving Practical Business Efficiency through Bottom-Up Data Culture Innovation

Overcoming the limitations of a 20-year legacy system to reduce reporting time and resolve data discrepancies

Developing over 30 practical dashboards led by field users

A phased expansion plan focused on power users to achieve 25% Tableau usage among all management staff by 2026

Hyundai Mobis has overcome the limitations of a legacy analysis system used for 20 years and established a field-led self-service BI system through Tableau Server. Unlike the typical top-down approach, they adopted a bottom-up method led by field users, spreading an analytical culture and achieving significant improvements in reporting time and decision-making speed. Here’s Hyundai Mobis' journey of innovation.

About the Company

Hyundai Mobis, headquartered in South Korea, is a world-renowned automotive component specialist operating three main business units: system solutions, module manufacturing, and A/S parts and accessories. They hold the 6th position among global automotive component manufacturers and lead in innovation in autonomous driving, electrification, and connectivity technologies. Hyundai Mobis supplies core components to global automakers, including Hyundai-Kia and Volkswagen, based on their expertise in lamps, cameras, radars, and other key electronic parts.

Among these, the service parts business unit is particularly significant. It manages the quality of after-service, which customers experience after car production, and operates a complex global supply chain. They manage approximately 10,000 items per car model and a total of 2.8 million parts for 205 Hyundai-Kia car models.

The Challenge

The Complexity of the Service Parts Business and the Limitations of a 20-Year Legacy System

The reality of genuine parts supply in the service parts business unit is complex. Different parts are required for each model, engine, and option of Hyundai-Kia cars, and many parts have a monthly demand of only 50 to 100 units. Despite this low-volume, high-variety structure, they must meet the strict service standard of supplying urgent backorders for commercial vehicles like taxis and buses within 8 hours.

Another major challenge was the personalized data management system. Query files were stored on individual PCs, making it difficult to access or find company-wide information. This led to significant time and resource consumption in extracting and updating data for management points, and different interpretations by individual users could cause discrepancies during meetings.

Before implementing Tableau, a lot of time and resources were repeatedly spent on summarizing daily, weekly, and monthly performance metrics, and discrepancies in data interpretation and perception among users often occurred. Now, as long as the data input is accurate, anyone can check and share the same structured dashboard in real-time, significantly reducing report writing time. We hope to use Tableau for quick decision-making during meetings and KPI reviews in the future.

How Tableau Helps

Bottom-Up Innovation through Tableau

Based on past system implementation experiences, Hyundai Mobis chose a "systematic verification process and phased approach" strategy. This involved PoC (Proof of Concept) and pilot testing to ensure stable deployment.

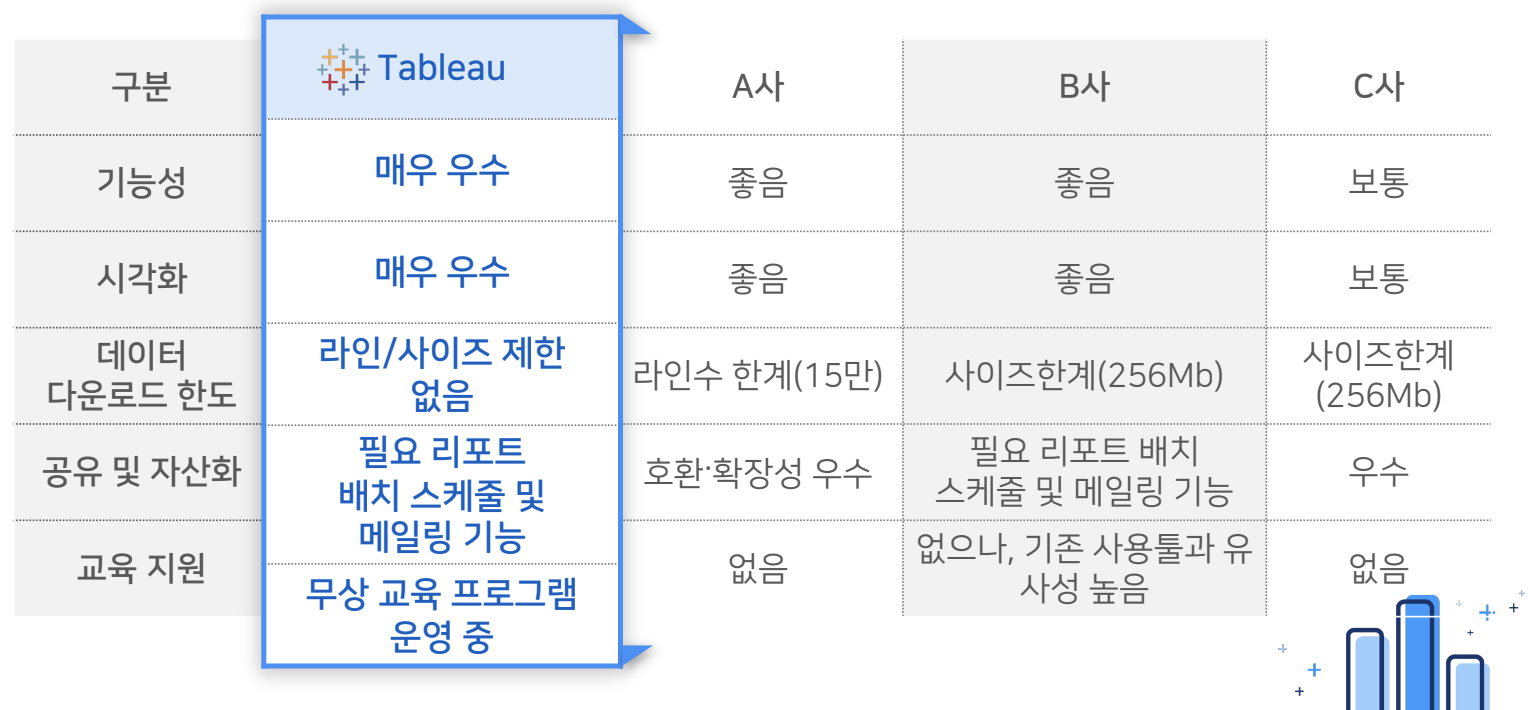

After evaluating several analysis tools, Tableau Server was selected for several reasons:

- Handling Large Data Volumes: The A/S parts business unit deals with millions to hundreds of millions of data points. Tableau can handle such large volumes without restrictions on file size or number of lines.

- Automation Features: Batch scheduling and subscription services automate repetitive tasks, making it suitable for large-scale operations.

- Ease of Expansion: Free training programs and a large pool of experienced users allowed for rapid adoption.

- Powerful Visualization: Intuitive visualizations help field users easily understand and share analysis results.

[The evaluation of Tableau during the analysis tool selection process]

A Quiet Revolution Starting from the Field: Nationwide Change Management

The pilot project was led by 30 power users who perform over 100 queries daily and 8 members of the Service PI Promotion Team. They conducted a 1-night, 2-day offline training session at each business site across the country and managed changes systematically through Microsoft Teams, encouraging active participation from field users.

During two internal competitions from December 2024 to August 2025, over 30 practical works were submitted. These were not just theoretical exercises but real solutions that could be immediately applied to actual business operations.

"Most companies create dashboards or BI tools at the top and then push them down. We chose the opposite approach, starting from unstructured analysis and moving upwards." - Inkyu Ryu, Senior Manager, PI Promotion Team, Hyundai Mobis

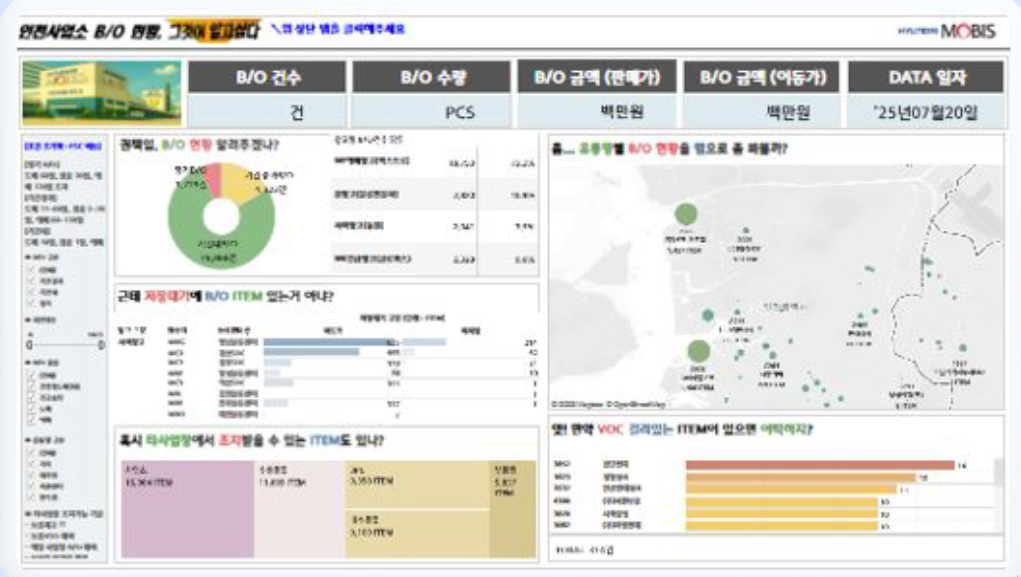

One notable work was the backorder status analysis dashboard, which helps solve backorders—parts requested by customers but not yet supplied. By simply changing the filter, this dashboard can be used across all 22 business sites nationwide.

The best work, the Voice of Customer (VOC) analysis dashboard, was designed with a systematic structure that allows drilling down from an overall view to detailed items. A red button leads to detailed analysis, and a back button returns to the main screen, making it a highly complete work that can be used from executives to field managers.

Backorder Status Analysis Dashboard

VOC Analysis Dashboard

Practical Changes Brought by Data

The pilot satisfaction score for Tableau at Hyundai Mobis was 4.5 out of 5. The most significant change post-implementation was the improvement in business efficiency.

"Before Tableau, a lot of time and resources were repeatedly spent on summarizing sales performance each week. Discrepancies in data interpretation and perception among users were also common. After implementation, as long as the data input is accurate, anyone can check the same structured dashboard in real-time, eliminating report writing time and noticeably speeding up decision-making during meetings and reviews." - Inkyu Ryu, Senior Manager, PI Promotion Team, Hyundai Mobis

A particularly meaningful change was that "all employees see the same data and make judgments based on the same criteria." This led to clearer and more consistent decision-making in sales strategies and resource allocation, which in turn improved execution.

Roadmap to the Future: Building a Sustainable Data Culture

Hyundai Mobis plans to expand Tableau usage in three phases by 2026. Starting with 30 power users in 2024, they aim to increase this to 110 power users and 80 general users in 2025, and further to 140 power users and 110 general users in 2026. The goal is to have 25% of the approximately 1,000 domestic management staff in the service parts business unit using Tableau.

Currently, they are standardizing the 30 works from the competition into 7 groups and 21 detailed categories (such as inventory management, logistics hub status, and distribution network status). After standardization, they plan to maintain continuous interest and improvement through a subscription service for executives.

The Tableau Difference

The Core of Innovation: User-Centric Approach

The most significant lesson from the Hyundai Mobis case is the "power of user-led change." As Inkyu Ryu said, "Because it was created from the bottom up, users have a sense of ownership." Field users designing and implementing the necessary analyses naturally improved their understanding and utilization of data.

As of 2025, Hyundai Mobis has combined Tableau with field-led participation to establish a data-driven decision-making culture. This bottom-up innovation model has become a benchmark for other companies, demonstrating that the value of data is fully realized when implemented at the field level.

" Our journey is not over yet," says Inkyu Ryu. This field-led innovation has become a solid digital foundation for Hyundai Mobis to move towards a greater future and is setting a new standard for true data culture innovation.