Nippon Gases moves its data-driven model forward with Tableau

Consolidation of all analytics in 13 European countries

Improvement of predictive maintenance of production plants

Identification of supply-chain inefficiencies

Nippon Gases, part of Nippon Sanso Holdings Corporation (NSHD), is one of the leading suppliers of industrial and medical gases in Europe. With over 150,000 customers in sectors as diverse as metallurgy, wastewater treatment, healthcare and the food, chemicals and pharmaceuticals industries, it is present in 13 countries, with a range spanning anything from the most efficient supply option to applications technology solutions tailored for every customer or partner. And it does all this with a clear vision: to create social value through innovative gas solutions that increase industrial productivity, improve human wellbeing and contribute to a more sustainable future.

The Information Technology (IT) department provides global support to Europe based on the principle that digitalization is the basis for innovation. In this respect, Nippon Gases is firmly committed to new technologies, and has set itself the goal not only of optimizing its efficiency, but also of improving customer experience and service.

We are changing our mentality to more robust, data-driven decision making.

Consolidation of analytical tools in Tableau

The importance of data is ingrained in the company DNA, and the company has always paid particular attention to analytics. This vision was enhanced even further after its incorporation into NSHD (at the time TNSC - Taiyo Nippon Sanso Corporation) in 2018. As director of Enterprise Applications at Nippon Gases, Elena López recalls this “was a turning point for us, because the European business had to start operating independently, and with that in mind we had to manage all our own applications”. It was at this point that the company placed its trust in the supplier it already had, Tableau, to cover its analytics needs.

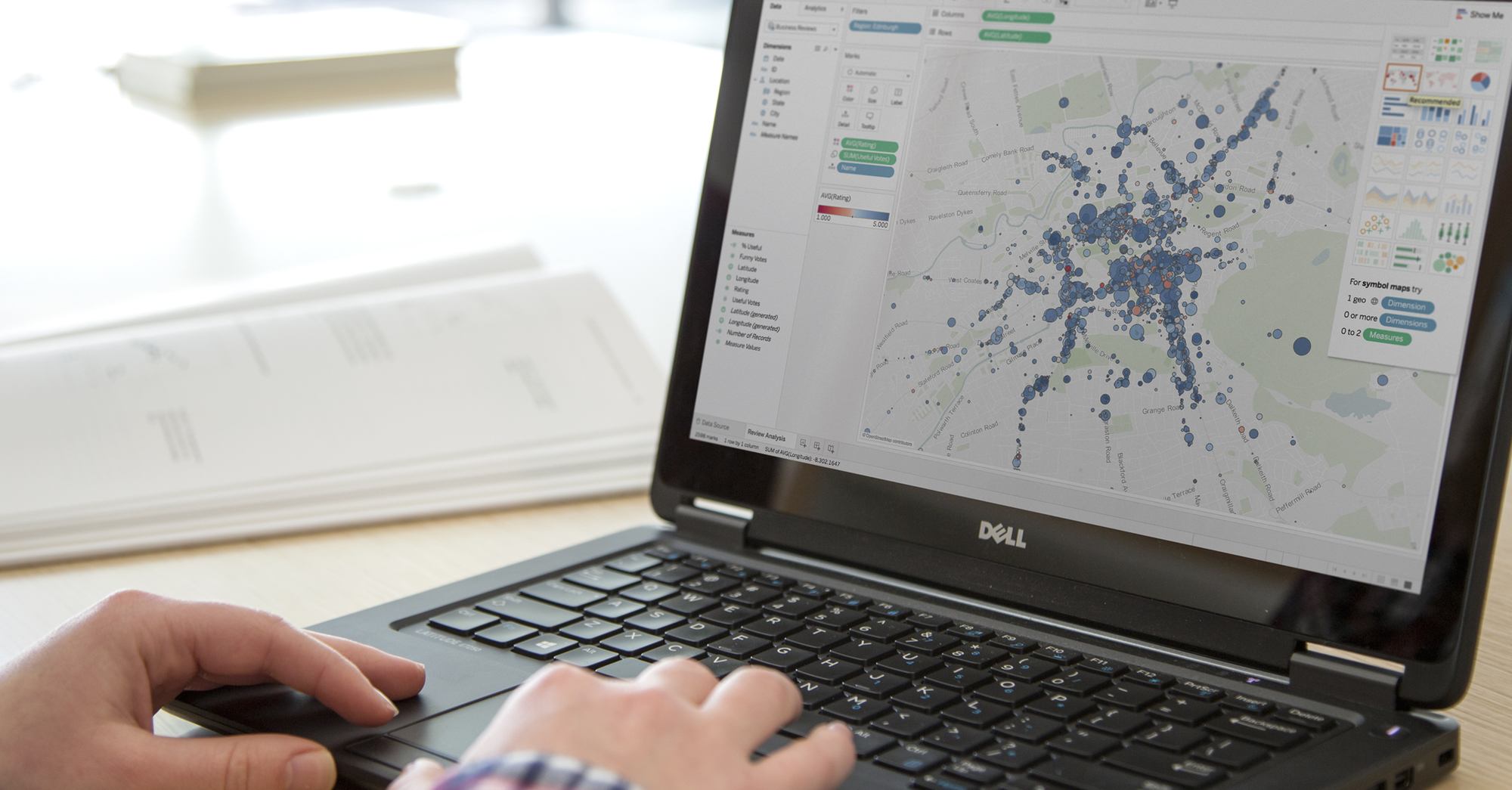

The initial situation was characterized by the existence of diverse analytics tools. “We couldn’t maintain our entire portfolio of analytics tools and we took advantage of the situation to consolidate,” the director points out. Despite the fact that, of the three tools implanted in the organization Tableau was not the most widely-used one, the balance tipped in its favor because “it was the one we saw as best placed on the market, with extremely good visual capacities. And on top of this it was easy to learn and simple to use”.

Cross-cutting application of analytical capacity throughout the organization

After a successful initial phase, when efforts focused on the migration of the rest of the analytics tools to Tableau, the latter has become an absolutely cross-cutting solution at Nippon Gases. “Although there is still some way to go in terms of implementation in certain businesses and regions, Tableau is present in many areas of the company, adapted and focused on the needs of each department,” says Ángel Montero, the company’s Data Analytics Manager.

Implantation began in the Operations department, as this was where it had been used most intensively in the past, and it quickly expanded to other departments like Accounting, Accounts Receivable, Distributor Sales, Accounts Payable to suppliers or the Technical Services department for all the operations of technicians dealing with installations, corrective or preventive maintenance etc.

“In Accounts Receivable, for example,” Elena López explains, “it plays a fairly significant role, because for us, financial KPIs are very important, such as (Days Sales Outstanding) or aging in order to see, customer by customer, what the situation is in terms of payment collection, default, deviations, etc., and make decisions based on this”.

We have to adapt the technology to the people, creating a governance model that allows analytics to be incorporated into employees’ everyday routine.

Optimization of efficiency in the supply chain

Given the size of Nippon Gases, with 130 production plants and over 600 trucks undertaking distribution to supply its broad network of customers throughout Europe on time, the Enterprise Applications Director points out that “our main cost in our production and distribution process is always energy and transport, so many of the analyses we carry out will optimize these two areas”.

As such, the Operations department plays a leading role. Jesús Gallego, the European Director of this department, which covers the air separation plants that produce oxygen, nitrogen and argon, and the coordination of distribution, explains how the analytical capacity provided by Tableau translates into improved processes and cost savings.

Likewise, the analytical power Tableau provides is also used to make proactive decisions. Jesús Gallego illustrates this point by explaining how analytics are applied to the process data of a compressor in a production plant. “By analyzing all of the variables that are involved and visualizing these calculations, Tableau can give us an early warning before an incident such as overheating occurs”.

Forewarned, the Operations department can make preventive decisions, helping to improve the availability and reliability of the production plant. “Without Tableau, this could not be have done previously, because we had no way of visualizing so much data,” says the Director. It is now also possible to gain a complete overview of all of the production stops that have occurred in plants, and as a result the cause will sometimes lead to a technical bulletin being sent out to the other plants in order to prevent similar incidents.

The advantage of Tableau lies not only in massive process automation, but also in the fact that if changes occur in consumption patterns, the update is automatically reflected in the analysis, allowing for improvement in the service provided to customers and ensuring a continued, reliable supply of gas in line with their needs.

Tableau has contributed to the democratization of data that was previously kept within a small group of people and is now shared and accessible to the rest of the organization.

Data democratization

From Jesús Gallego’s perspective, “Tableau has contributed to data democratization,” with information that was previously kept within a small group of people with ample experience (heads of plants, logistics, etc.) now shared and accessible for the rest of the organization. The centralization of all the information in a single place, and the ease with which it can be visualized, has brought with it a change in decision-making with a data-driven model.

Elena López maintains that “thanks to Tableau, decisions previously based on highly experienced people in our business are now also supported by objective data, which tells us where and how to act”. As a result of this, Jesús Gallego adds, “we can now identify opportunities for carrying on with this process of continuous improvement which, without Tableau, would have gone unnoticed among the huge amount of data we handle”.

The next step, according to Angel Montero, is the company’s analytics maturity process, with the goal of becoming a Data-Driven organization, so that every member will be able to consume data in a democratized, unified manner in order to make better decisions in line with the organization's strategic objectives and goals at all times. To achieve this, there is a cultural challenge that will have to be overcome, adapting the technology to the people and creating a management model that allows analytics to be incorporated into employees’ everyday routine.