Kulicke & Soffa achieves up to 70% revenue growth by building Tableau analytics from the ground up

>65% revenue growth in 3 years

96% fewer defects per machine

Halved non-productive labour hours

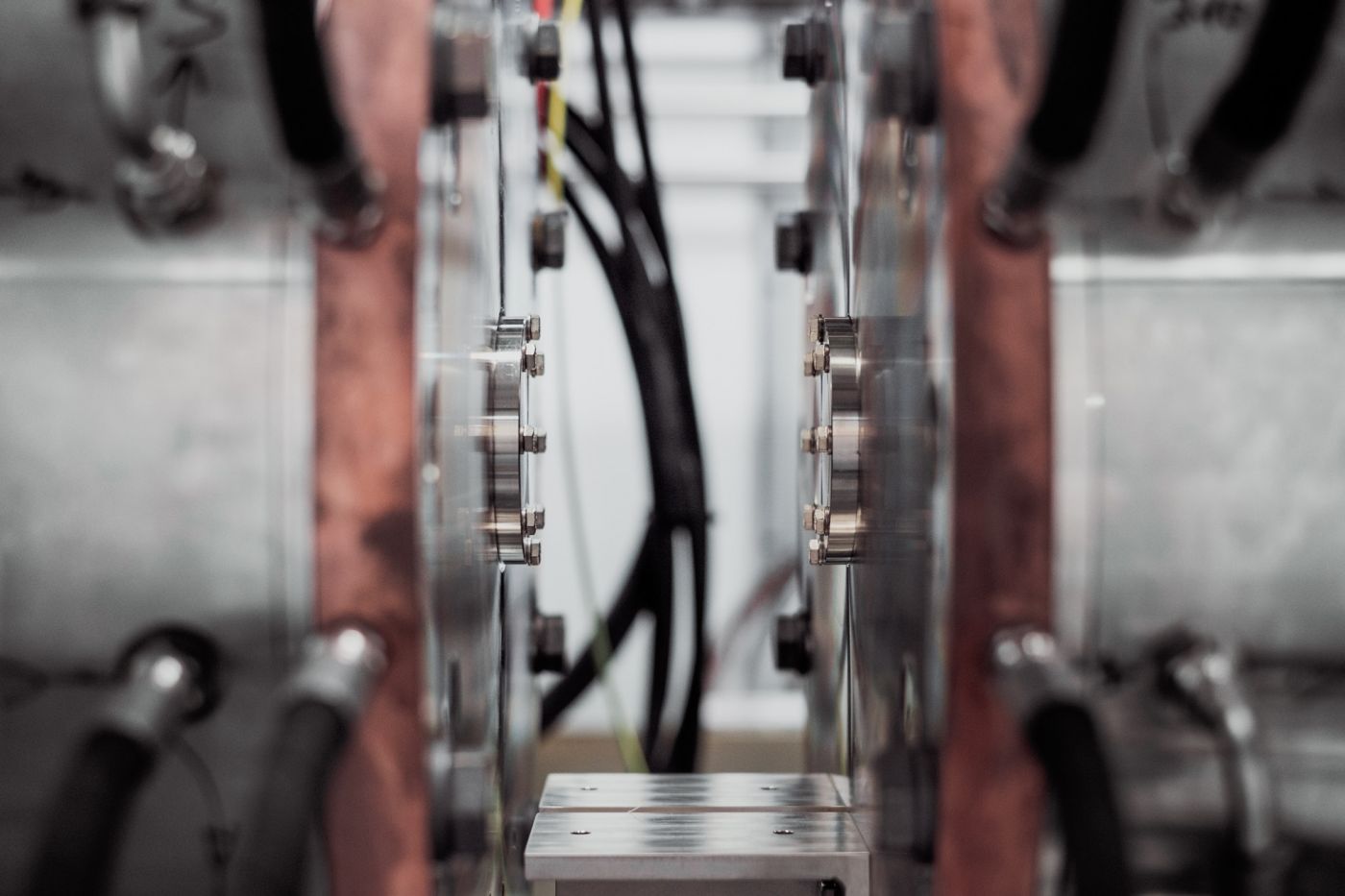

Kulicke & Soffa (K&S) is a leading provider of semiconductor packaging and electronic assembly solutions supporting industries such as automotive, communications and computing. As a pioneer in the space, K&S has provided customers with market-leading packaging solutions for decades, helping them meet the challenges of packaging and assembling next-generation electronic devices.

Senior Director of Operations Engineering TK Loh leads a team in the Singapore corporate headquarters to optimise operational excellence throughout the manufacturing value chain, from design and production to shipping, supply chain management and after-sales services. He shares how K&S built a system and culture of analytics from the ground up with Tableau, maximising productivity and revenue growth by improving production yield and quality, reducing non-productive hours and identifying defective parts.

Tableau empowered us to understand the power of data analytics, and combined with our domain knowledge, we built a success story from the ground up.

Unlocking the power of analytics with domain knowledge

Before the business started investing in data analytics, data was “all over the place”, with different versions of Excel sheets on different people’s laptops, TK shared. Solving problems was like looking for a needle in a haystack, for they did not know where to find the data they needed in the first place, or which problem to tackle first.

“We were facing a data disaster,” he adds. “Our company was growing exponentially, with ever-increasing amounts of data, without the ability to make fact-based decisions. It was all based on emotion or individual perception, leading to sub-optimal results.”

With three major production lines in Singapore producing more than 10,000 units of high-precision semiconductor equipment, it was challenging to identify problem areas without clean and reliable data, much less prioritise. This is why TK chose to build an analytics system by bringing in the “domain knowledge experts” – people who know the work processes and are most familiar with what data they need to solve problems.

“Any data analytics system needs two components: the data analytics platform, and the domain knowledge to use it in the most effective manner,” he emphasises. “The people with domain knowledge know their area well, but they were not familiar with data analytics.”

“Tableau empowered us to understand the power of data analytics, and combined with our domain knowledge, we built a success story from the ground up,” TK says.

Smart manufacturing powered by data analytics has helped the company achieve 65% revenue growth over just 3 years of Tableau adoption.

Effective decision-making yields exponential results

The first crucial step K&S faced before starting analytics was to clean up their massive store of data, before they were able to start creating meaningful dashboards. Engineers helped to identify the critical data points that will affect production yield and quality, which were aggregated into a common database. The next challenge was to build dashboards that could tell a story and enable decision-making.

“Only if your dashboard can take you through the decision-making process will it be truly meaningful,” shares TK. According to him, the key is to identify the desired outcome – for example improve the quality of a production line – start with the main contributing factor, and drill downwards to the least significant, to ensure resources are allocated efficiently.

Within three years, TK and his team has significantly improved production quality and reduced cost with Tableau, reducing defects per machine by 96% and cutting non-productive hours by at least half. Smart manufacturing powered by data analytics has helped the company achieve 65% revenue growth over just 3 years of Tableau adoption (as of 2018).

With these visible results, the team’s success created a ripple of behavioural change throughout the business, with the C-suite taking notice and investing heavily in data analytics.

Tableau didn’t just want to sell us the product, but they also wanted to help us use the product to make decisions that could help our business.

More than a software: A business-centric partner

When asked “Why Tableau?”, TK advocates Tableau’s strong management support and a genuine investment in solving business problems for customers.

“Many people in the market are more interested in selling us the software, while some claim they are selling a solution,” he says. “But what we were looking for was a partnership that helps us bring analytics into the business step by step, because we are facing a very sceptical population of employees that know next to nothing about visualisation and analytics.”

He reflects, “Tableau didn’t just want to sell us the product, but they also wanted to help us use the product to make decisions that could help our business.”

TK also cites strong management support, from the ground level to senior management and even up to the global level, referring to a time when Tableau’s Chief Product Officer Francois Ajenstat visited the K&S Singapore office. “How many companies do that?” He quips.

“In life you can give someone a fish, or teach them how to fish. Tableau’s management is more interested in teaching me how to fish,” he says, quoting a well-known proverb.

Semiconductor production is an important part of Singapore’s economy, and we have to stay competitive or risk being overtaken by other industry players. Smart manufacturing with Tableau helps us maintain our competitive advantage.

Manufacturing a smart future

Moving forward, the team hopes to roll Tableau out across the enterprise to improve overall decision-making processes in the supply chain, finance and engineering departments. They will help each team by consolidating their relevant data into a database, defining decision-making metrics and training them to do self-service analytics.

“Coming back to my original point, I believe implementing Tableau cannot be a push, but rather a pull through visible results,” TK reiterates. “There is a saying, ‘You can lead a horse to water but you can't make him drink.’ When you showcase your productivity gains through data-driven decisions, people will naturally want to acquire the skill set.”

In the years ahead, K&S will continue to scale Tableau across their research and development offices in the United States and Israel as well as their factory in China to improve design and manufacturing processes. They are also working on exciting projects in the predictive modelling space, building mathematical models in R and Python, and visualising them in Tableau to calculate the probability of a machine part failing in the next few years.

“Semiconductor production is an important part in Singapore’s economy, and we have to stay competitive or risk being overtaken by other industry players,” shares TK. “And smart manufacturing with Tableau and machine learning helps us maintain our competitive advantage.”