Hankook Tire leads digital transformation and improves business efficiency and agility with Tableau

Improved the efficiency of reporting by about 75% by creating an enterprise-wide data culture

Led the digital transformation of the manufacturing industry through the smart factory project

Provided support so that business departments can quickly respond to changes in external conditions

Hankook Tire & Technology (Hankook Tire), No. 1 company in the domestic tire market, manufactures tires for various types of vehicles, e.g. passenger cars, electric vehicles and SUVs. In addition, its top-tier technological competitiveness is recognized around the world so much that Hankook Tire was ranked No. 1 in a tire test conducted by a famous European automotive magazine in 2020. As it succeeded in developing a road risk detection solution and a model for predicting the physical properties of tire compounds based on the AI and deep learning technology in line with the transition to the age of the 4th Industrial Revolution, it is leading the digital transformation of the tire industry. It is producing tires in its 8 production bases in Asia, the US and Europe, and selling them in more than 180 countries around the world, and its sales amounted to about 6.8 trillion KRW in 2019. It employs over 20,000 people around the globe.

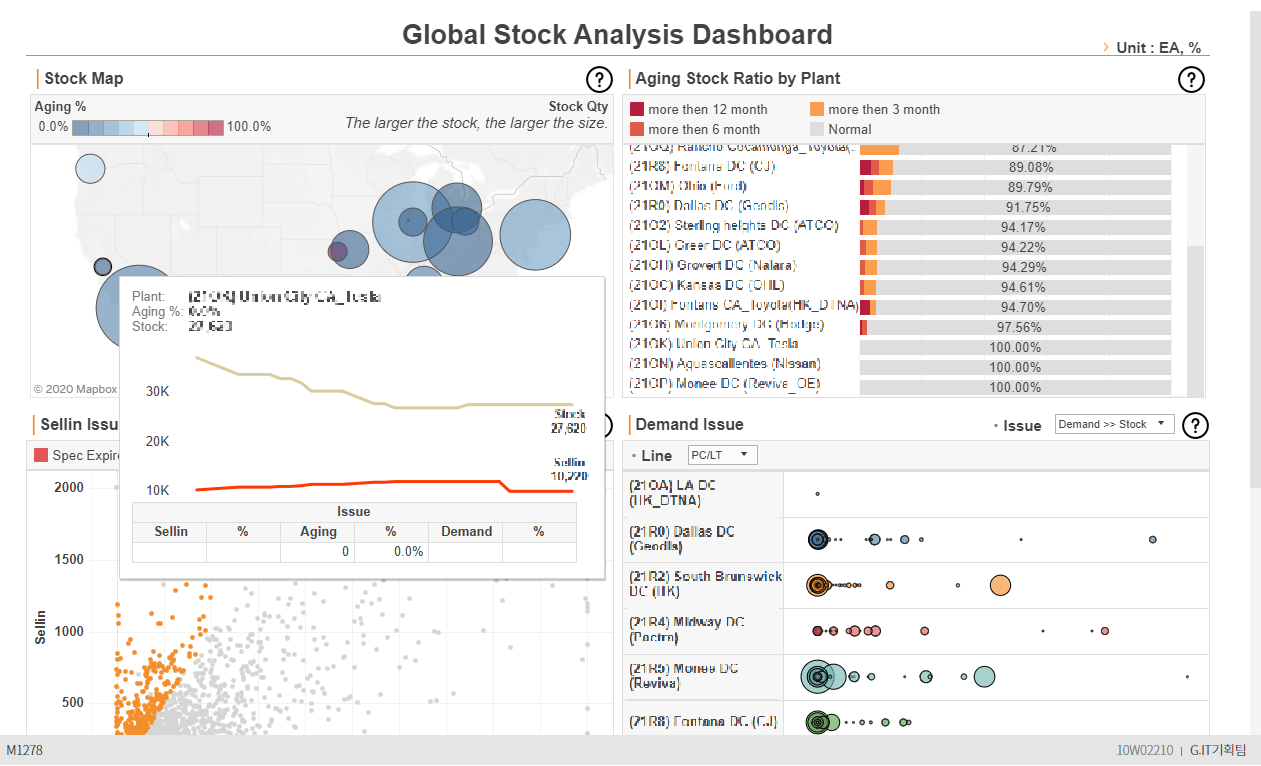

Hankook Tire is using Tableau for digital transformation, creation of the data culture, data-based decision-making, self-service analysis and visualization by employees in business departments and the smart factory project. It is using Tableau to improving business efficiency while finding and sharing meaningful insight from vast amounts of data at the fastest speed and leading the growth of business in the face of changes in the external environment. In particular, it is building the integrated data governance system, which connects the data of 8 production plants around the world and developing the big data analysis program necessary for advancing the smart factory with Tableau.

Tableau is recognized as a pioneer in modern BI area, and has outstanding references in Korea. Through partnership with Tableau, Hankook Tire is reinforcing data-based business support throughout the organization. We will continue to lead digital transformation in the manufacturing industry through collaboration and decision-making based on standardized data.

Reduced the reporting time by about 75% by creating an enterprise-wide data culture

Currently, Hankook Tire is using Tableau to analyze and visualize the business data necessary for management, finance, selling, products, manufacturing, production management and researches. And its employees use the dashboard shared across the whole organization to discuss and make decisions in real time.

It is improving such jobs as reporting, collaboration between departments and performance measurement by connecting Tableau to the enterprise-wide data warehouse (DW), building 8~9TB (terabytes) datasets necessary for analysis and standardizing data. Also, it is processing up to 300,000 lines of data fast.

In the past, if frontline employees sent ideas about data analysis and report development to the IT, the IT Department built an appropriate dataset, developed the report, made modifications and improvements through collaboration with frontline employees. It used to take a lot of time before actual use.

In addition, as data was not standardized, it was difficult to build an analysis and reporting system that can be applied consistently to different jobs.

Meanwhile, at Hankook Tire, frontline employees’ demand for using the data of the system essential to its global business to develop reports and derive insight that can lead to improvement of business performance is increasing. As a result, the management wanted to create a data culture based on an enterprise-wide analysis system, and actively encourage frontline employees to improve their data use proficiency.

Hankook Tire introduced Tableau because the drag & drop-based intuitive visualization enables the employees of all business departments to quickly develop sophisticated reports early using only IT technology and education support. It also regarded the fact that IT employees can instantly respond to the requirements of frontline employees as a big advantage.

After adoption of Tableau, Hankook Tire implemented the 'self-service analysis’ environment in which the employees of all departments can analyze standardized data. It standardized various kinds of data, and established consistent standards for efficient data-based collaboration between different organizations in the company. The employees of different departments use Tableau to universally utilize data for their work based on common understanding of data.

The employees of frontline departments are freely exploring the data that can be utilized for report development and concretizing requirements with easy-to-use Tableau. As a result, the IT Department is taking charge of only report development and data management with a high level of difficulty, and concentrating on strategic business impacting the entire company in terms of business digitalization.

Thanks to the easy data processing function of the GUI environment of Tableau, Hankook Tire reduced the time it takes to develop 1 report by 75% from about one month to one week. Frontline employees can visualize vast amounts of data at the speed of light using the dashboard shared in the Tableau portal, and the Tableau dashboard embedded in the 7 business systems of the company.

Lee Jae-sang, G.IT Planning Team, Digital Strategy Department, Hankook Tire, said, “As Tableau is popularly used in various industries, including manufacturing, and in universities, it is very easy to use. In particular, as it is possible to develop dashboards, seldom used in Korea industry, e.g., Work Cloud and Heat Map, it helps improve business processes based on analysis and insight.”

Currently, the management of Hankook Tire must make critical decisions in real time in response to changes in the global business environment. Connected environment based on Tableau enables the management to talk with frontline employees and make decisions based on key business performance indexes anywhere and anytime.

Jae-sang said, “Tableau is recognized as a pioneer in modern BI area, and has outstanding references in Korea. Through partnership with Tableau, Hankook Tire is reinforcing data-based business support throughout the organization. We will continue to lead digital transformation in the manufacturing industry through collaboration and decision-making based on standardized data.”

Currently, the IoT and AI based smart factory is a hot topic in the manufacturing industry. As data analysis using Tableau makes it possible to find the insight necessary for improving the reliability and efficiency of manufacturing processes by integrating various kinds of data generated by smart factories, it is key to gaining top-tier competitiveness in the digital age.

Led digital transformation through the smart factory project

Currently, the manufacturing industry is improving operating efficiently, productivity and product quality and reinforcing safety by digitalizing the value chain and business environment and combining advanced technologies, e.g. 5G, AI, IoT and robots. Hankook Tire is conducting a project to improve the smart factory technology based on the data it has accumulated over the years through its operation of the tire manufacturing business, e,g. supply and demand of materials, design, R&D, production and distribution.

Hankook Tire R&D Center and production headquarters, in charge of the project, are using Tableau to quickly visualize vast amounts of data that are generated in seconds by the various factory facilities of Hankook Tire. They are aiming to use the Tableau dashboard to set apart the data necessary for smart factory applications, e.g. equipment maintenance, management and development, analyze the data through charts and logic, and create a data-based decision-making culture.

In particular, Hankook Tire R&D Center provided help with combining the AI technology with the model for predicting the physical properties of tire compounds by using Tableau to visualize the result of tire compound analysis in the Amazon environment.

Hankook Tire went a step further, and it is planning to create a system environment for quickly collecting and providing the data of global offices and factories and reinforce data interworking so that the headquarters’ innovation initiative and data standardization system can be expanded to its offices around the world.

Lee Gwang-won, G.IT Planning Team, Digital Strategy Department, Hankook Tire, said with emphasis, “Currently, the IoT and AI based smart factory is a hot topic in the manufacturing industry. As data analysis using Tableau makes it possible to find the insight necessary for improving the reliability and efficiency of manufacturing processes by integrating various kinds of data generated by smart factories, it is key to gaining top-tier competitiveness in the digital age.”

Provided support so that business departments can respond quickly to changes in external conditions

Before Tableau was introduced, at Hankook Tire, the data used for business decision-making and performance evaluation was not transparent due to the data silos of the system. In fact, as data was often deformed due to the supervision of frontline managers in the process of data retrieval, sorting and reporting, management diagnosis found that the demand for standardization of data and systematization of analysis has been rapidly increasing. Unreliable data was an obstacle to agile decision-making and responding to changes.

Hankook Tire is sharing business data in the report sharing portal of Tableau in real time so that business can be conducted based on more accurate data and analysis results in response to the quickly-changing business environment. In this portal, frontline employees use the Tableau maps or graphs to check Hankook Tire products and demand data of each region of the world.

In the past, as it used to take 8 hours to update the global inventory and sales data of Hankook Tire, it had difficulties responding to a crisis, but after adoption of Tableau, it is now possible to provide the data to employees in charge of marketing, logistics and sales in 30 minutes.

“To stably operate business in the rapidly-changing world, we must reduce and optimize costs,” said Lee Jae-sang, G.IT Planning Team, Digital Strategy Department, Hankook Tire. “We could use Tableau to enable frontline employees to share the sales and inventory data of our business operations around the world in real time, and expand the scope of available inventories from the sales perspective, and improve the resiliency of business.”

The management and financial management division introduced the Tableau dashboard and significantly reduced the reporting time, and they are planning to become the first to convert all Excel reports to Tableau.

Tableau makes it possible to share data and reports in real time, and easily find business opportunities amid rapid changes using the function for developing reports with agility. Hankook Tire, making diverse efforts to lead the age of 'digital transformation,’ is expected to use the self-service BI analysis of Tableau to maintain its leadership position as a premium brand in the global market.

In particular, the financial management division where Tableau takes up a large part of its work is developing its own reports without the resources of external IT experts based on the large datasets built with Tableau.. Also, the cost management division is using the mail subscription function to share the intuitive dashboard, which shows budget usage by department and team.

Jae-sang said, “Tableau makes it possible to share data and reports in real time, and easily find business opportunities amid rapid changes using the function for developing reports with agility. Hankook Tire, making diverse efforts to lead the age of 'digital transformation,’ is expected to use the self-service BI analysis of Tableau to maintain its leadership position as a premium brand in the global market.”

Hankook Tire’s partner DFOCUS, made many contributions during the introduction process for Tableau. DFOCUS had broad experience in BI implementation and helped channel the various demands within Hankook Tire, to tangible services through Tableau. In the early stage DFOCUS mainly helped develop Tableau dashboards and train staff yet expanded support to include aiding data development and consulting visual designs to increase satisfaction levels in project participants and with the final outcomes. Furthermore, DFOCUS provided a wealth of knowledge to Hankook Tire during the Tableau implementation process, such as references and methodologies encompassing BI and information sectors, helping Hankook Tire find the best solutions to cater to their needs.