Using Tableau to Visualize Massive Data in Smart Factories

Improving the Accuracy and Speed of Decision-making

Cultivating a Data-driven Culture

Background to Implementation

The Essence of Semiconductor Manufacturing is Rapid Response to Unforeseen Circumstances

First inventing NAND flash memory in 1987, then establishing 3D flash memory technology in 2007, KIOXIA Group continues to be a global leader in the semiconductor memory industry. Within KIOXIA Group, the KIOXIA Iwate Corporation (“KIOXIA Iwate”) has implemented the largest manufacturing building and most advanced facilities, and it is responsible for production of BiCS FLASH™ 3D flash memory.

“Since semiconductor development and manufacturing test the physical limits of the process, they are different from other types of manufacturing and are similar to agriculture, in a sense,” said KIOXIA Iwate President and CEO Koichiro Shibayama. He explains that, when pushed to the physical limits, unexpected events are more likely to occur and it is not uncommon for things to deviate from the plan. “The essence of this industry is actually dealing with these unexpected events in itself. This is what makes it so hard for other companies to enter the industry.”

To enable this, it is essential to rapidly gather massive amounts of data generated at factories and make quick management decisions with respect to circumstances that are changing day by day. For that reason, KIOXIA Iwate is working to transform its plants into smart factories, and these factories generate billions of units of data on a daily basis, Shibayama explains.

“For example, if manufacturing equipment breaks down, we have to quickly determine what kind of specialist to call and what parts to replace. Semiconductor supplies, which are already strained, may be delayed if these decisions come too late. Of course, manual processing of this incoming data will never get it ready in time. Instead, we need a way to instantly see the data with one click and use it in our decision-making right then and there.”

Tableau Implementation and Operation

One Year After Implementation, Half of Personnel are Tableau Users

What should we do to address these needs? The answer that KIOXIA Iwate drew to this conclusion: Tableau.

“We started developing a plan to create a venue for sharing information in May 2020, but we didn’t have a specific tool in mind at first,” said Naoyuki Ando, General Manager of the IT Promotion Department at KIOXIA Iwate. They started out by having outside consultants come in to teach them the tools and state of affairs. “Then we had them suggest three types of products, and in July 2020 we decided to use Tableau.”

The IT Promotion Department had never used Tableau before, so they began by mastering the tool through training provided by Tableau Software, Inc. Tableau Software, Inc. was also asked to handle data collection and other environment-building, and implementation took place between summer and fall 2020. Next, we began working on visualizing manufacturing data. Budget control was implemented for daily manufacturing activities, and data on equipment problems was shared.

In April 2021, we began operating dashboards for quality control (e.g. yield rates) and dashboards for manufacturing management that import data from production planning systems. In August 2021, manufacturing-related dashboards were expanded further.

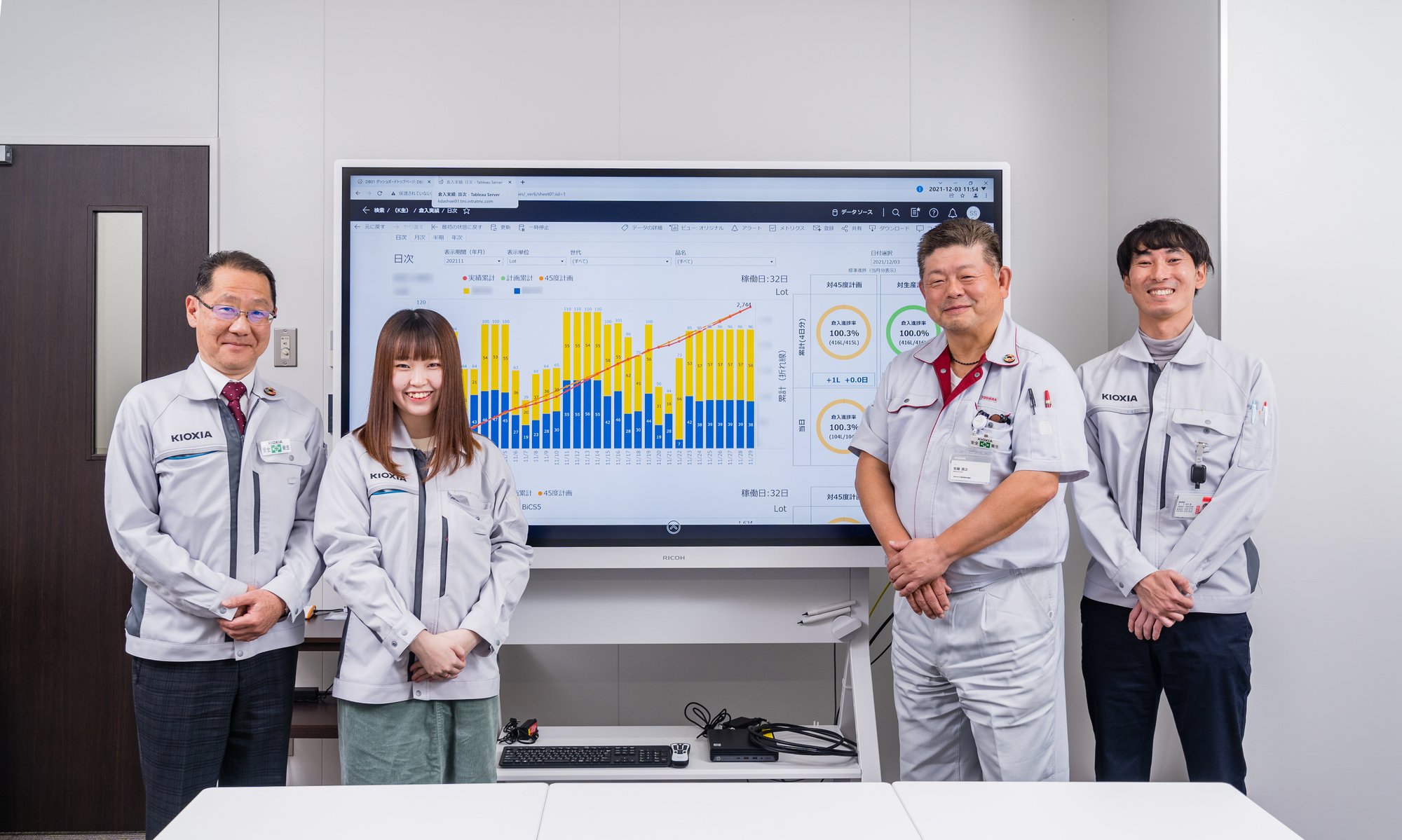

“Starting with around ten users initially, we now have approximately 500 people using Tableau, which is half of our company’s total workforce,” explains Sho Hironai, IT Promotion Lead in the IT Promotion Department of KIOXIA Iwate. “Ultimately, we want to expand Tableau to all personnel except frontline workers.”

We now have approximately 500 people using Tableau, which is half of our company’s total workforce Ultimately, we want to expand Tableau to all personnel.

Why Tableau?

Praise for Intuitive Controls, Support, and Easy Rollout

So why was Tableau chosen from among the three products considered? Hironai gives three general reasons.

First is that Tableau’s controls are intuitive, and Prep can be used to flexibly link up to various data sources. “Since there is a high volume of data involved, we especially appreciated how easy it is to filter data. Drill down and other features can also be used more flexibly than with other BI products.”

Second, Tableau provides a robust amount of data and strong support structure. If users have any questions, he says, they can look up many of the answers on the internet. If they still can’t resolve the issue, they can contact Tableau Software, Inc. directly. To make further use of these advantages, the company also signed up for Premium Support in November 2021 when they achieved 500 Tableau users.

Third is just how easy it is to roll out. “I have been using Tableau since the summer of my first year with the company. Although I had no experience with the program, I was able to create a dashboard after about two weeks,” said Shiona Yaegashi, IT Promotion staff in the IT Promotion Department of KIOXIA Iwate. If the user has received some simple training in advance, she says, almost nothing in Tableau should be difficult, and using the software should be fun.

Even inexperienced users can create a dashboard right away. It is easy to understand how data should be processed and expressed. Additionally, she says that the provided dashboards can be used to perform secondary processing on the user side.

Benefits of Tableau Implementation

Faster Creation of Reference Materials and Quicker Decision-making

Using Tableau in smart factories has yielded the following benefits.

Reports Created in Less Time

“Although there was already a system in place for collecting data from manufacturing plants in real time, Excel was used to aggregate this data and create daily reports,” explains Hironai. He reflects on how this process wasted two to three hours every day. “Most of that work is now no longer needed. We have cut down the time spent on creating reports by 78%.”

Improving the Accuracy and Speed of Decision-making

There has been an improvement in the speed of decision-making when a problem occurs on-site. Previously, dozens of relevant personnel needed to come together based on the reference materials created, but now they can simply look at the dashboard, have a discussion, and make a decision without meeting. Moreover, since everyone is looking at the same data, discussions will be more precise and to the point. The amount of time required to address a given issue is somewhere between half and a third of what it was before, although this varies from case to case.

Cultivating a Data-driven Culture

Using Tableau on an everyday basis is also changing the mindset of personnel. “More personnel are beginning their days by checking the status of things on their dashboard before beginning their daily work,” Ando explains. He adds that personnel are also showing interest in dashboards outside the manufacturing department. Some members of the accounting department have begun using dashboards. “There has also been talk of using the tools in areas such as electrical power usage analysis. Moving forward, I hope we can spread this company culture to other companies in the Group.”

We want to deploy Tableau not only for manufacturing sites, but also in facility management and accounting. We would also like to create a higher-level dashboard that is used to manage multiple other dashboards to make it easier to monitor issues and make decisions.

Future Developments

Capture a Wider Range of Data to Support the Independent Growth of Personnel

Although Tableau is currently used to visualize equipment data in factories, Shibayama says he would like to import more infrastructure data and data needed for decision-making at large plants such as chemical plants and similar facilities as reference material for management decisions. In the future, he adds, he would also like to conduct discussions with partners and other external companies based on this data in order to make external business decisions.

Meanwhile, he also says he expects Tableau to contribute greatly to creating an environment in which personnel can achieve independent growth. “There are many young staff at our company, but semiconductor manufacturing is a complex and difficult job in which many different matters are intertwined, making it difficult to master in a short period of time. Of course, we offer internal company training and the opportunity to be taught by more senior staff, but that will not be fast enough. However, with a system like Tableau, even staff who have yet to acquire the necessary skills have an easier time making proper decisions. I look forward to seeing this sort of system expanded further in the future.”

We want to use Tableau not only to visualize equipment data in factories, but also to import more infrastructure data and data needed for decision-making at large plants such as chemical plants and similar facilities as reference material for management decisions.