Samsung C&T: Redrawing Construction with Data

By integrating Tableau and TabPy, it's now possible to perform expert-level AI-based analysis without coding.

Complex procurement decisions are completed in just 10 seconds, achieving accurate price predictions well above the industry standard.

AI is being applied across all areas, from design to construction, accelerating the digital transformation of traditional construction.

Learn about Samsung C&T's innovative approach to complex procurement decision-making processes in EPC (Engineering, Procurement, and Construction) for large-scale plant projects using AI and machine learning. By combining Salesforce, Tableau, and Python in the SPM (Smart Price Model), Samsung is completing price predictions with 5 to 20 complex variables in just 10 seconds, achieving an increased accuracy level of about 10%, and significantly improving operational efficiency.

About the Company

Samsung Construction and Trading Corporation, based in South Korea, operates under the vision of "Creating a Better Future" and undertakes a wide range of construction projects, from skyscrapers and civil engineering works like airports and subways, to power plants such as combined cycle and solar power plants, and residential complexes like Raemian. They possess world-class competitiveness in the EPC large-scale plant business, as evidenced by their recent successful bids for global projects like the Qatar desalination power plant and the Saudi Aramco combined cycle power plant. Recently, they have been leading industry innovation through digital twin-based construction using construction data and foundational technologies.

The Challenge

The Digital Transformation Challenges Faced by Traditional Construction

Samsung C&T's Construction Division faced three major challenges in realizing their grand digital transformation vision:

- Data Acquisition: They needed to establish a governance system for collecting and utilizing unstructured data, secure big data and high-quality data, and ensure continuous monitoring and evaluation.

- Overcoming Data Silos: Data from different stages—design, procurement, construction, and operation—were managed separately, leading to a lack of communication. Given the industry's reliance on decades of knowledge and experience, integrating data was a significant challenge.

- Expertise: They needed AI engineers with domain knowledge to overcome these limitations. Additionally, they had to enhance data literacy, build reliable AI models, and continuously improve model performance.

AI has unlocked the value hidden in unstructured experience data. We need to break down the silos that prevent design, procurement, construction, and operation data from communicating with each other.

How Tableau Helps

An Innovative Partnership with Salesforce & Tableau

To tackle these complex challenges, Samsung C&T chose Tableau Server. Tableau's powerful data visualization capabilities, combined with the TabPy extension for Python integration, allowed them to consolidate AI, BI, and visualization into a single platform.

Tableau provided a one-stop environment for handling all processes from data analysis to AI model execution. This enabled the Smart Price Model to transform the results of complex machine learning and deep learning algorithms into intuitive charts and graphs, making it easy for procurement managers to understand and use.

In particular, the user-friendly interface allowed even non-programmers to perform advanced analysis with just a few clicks.

The Birth of the AI Procurement Solution SPM

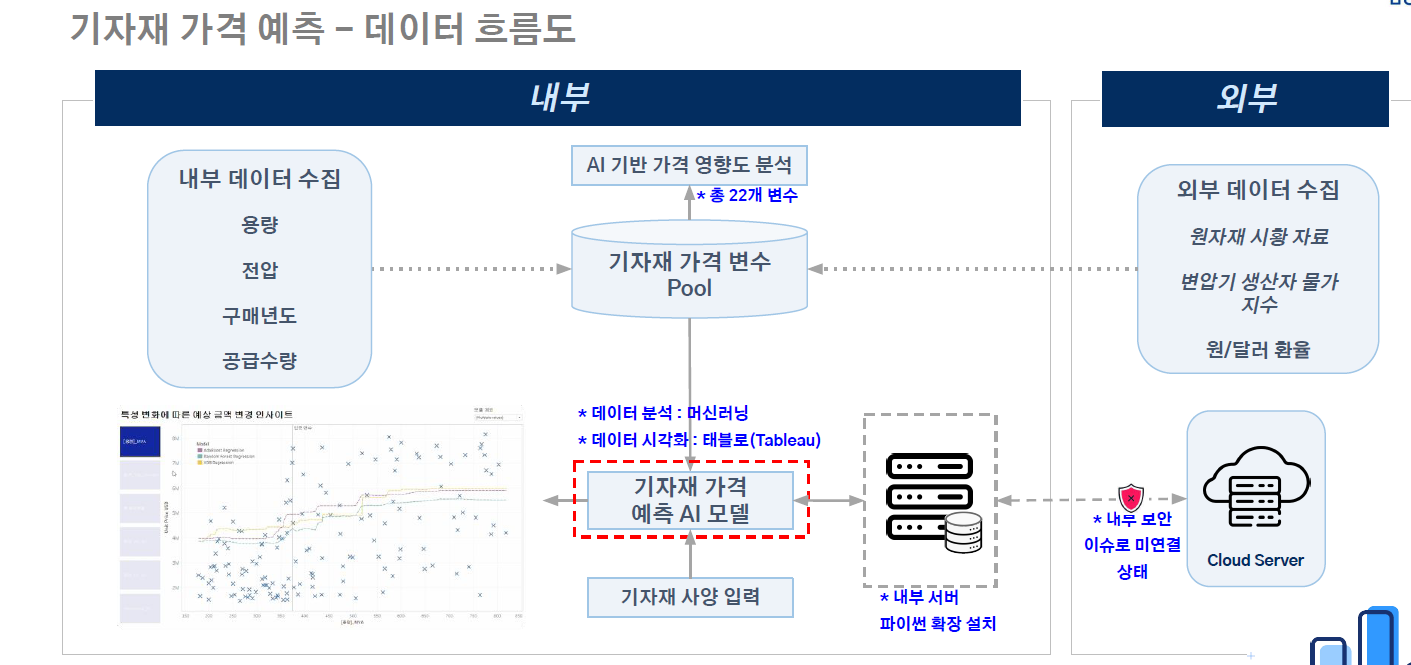

Samsung C&T developed an innovative AI procurement prediction system called SPM (Smart Price Model) based on Tableau. The goal of SPM was to collect internal and external data, analyze it using visualization tools, and automate the entire pipeline from preprocessing to training, prediction, and evaluation.

By leveraging integrated data, SPM utilized over a decade of procurement data, raw material indices, producer price indices, and exchange rates. The TabPy extension integrated Python's powerful programming capabilities with Tableau's BI tools.

Advanced AI algorithms combined the strengths of various prediction models, automatically identified key factors among dozens of variables, and presented complex analysis results in a visual format that anyone could understand.

A fully integrated environment was created, allowing users to train, evaluate, predict, and gain insights directly in Tableau, all with a single button click.

SPM demonstrated excellent accuracy, with an error rate of about 10% when validated against actual procurement data. In the industrial sector, an error rate below 10% is considered highly accurate, and even up to 20% is regarded as a good prediction.

Validation was conducted by comparing the actual prices of already purchased transformers with the predicted prices, and the error rate for three actual bidding projects was between 5% and 10%.

The Changes Brought by SPM

The most noticeable change since the introduction of SPM is the speed of work. Complex price analyses that used to take days are now completed in just 10 seconds. Procurement managers who are not familiar with coding can obtain expert-level analysis results with just a few button clicks.

This has allowed the procurement team to focus on high-value tasks such as developing procurement strategies, rather than repetitive work. In particular, SPM has completely replaced the time-consuming price verification stage in the traditional procurement process.

The success of SPM has also led to an overall improvement in the organization's data capabilities. Most notably, the development speed was impressive. With just one week of training from Salesforce, they were able to complete such a sophisticated AI tool within a few months, showcasing Tableau's excellent accessibility. The ease of use, accessible via a web browser, has made it simple for anyone in the organization to utilize.

"Can it predict like a 10-year expert? Can it visualize feature importance along with prices? Can it do all this in 10 seconds without coding? SPM answered all these questions." - Joshua Choo, Gas ENG Team Data Group, Samsung C&T

Continuous Innovation Toward the Future

Building on the success of SPM, Samsung C&T is accelerating the digital transformation of the entire construction industry.

For workforce resource optimization, they are developing a predictive model that simulates the optimal resource allocation plan by deep learning from past project workforce data.

In the design field, they have shortened the initial pipe quantity estimation process, which used to take days, to just a few minutes using an AI model that predicts material, size, and thickness.

In the construction field, they are continuously driving on-site innovations, such as developing AI models for optimal construction scheduling, managing progress rates automatically through drone image analysis, and enhancing on-site safety systems.

I believe the key to changing the construction paradigm lies in autonomous design. When the final piece of this puzzle falls into place, we will enter an era of digital twins perfectly synchronized with reality, redrawing construction.

The Tableau Difference

Growing Together with Salesforce

In Samsung C&T's innovation journey, Salesforce has played a role beyond just providing solutions, becoming a true partner in digital transformation. Through continuous communication with the procurement team, they have received feedback on which insights and analyses are most helpful in practice, leading to the development of better AI-based BI tools.

Based on the success of SPM, they are expanding its application to other procurement items and conducting ongoing pilot tests. They are also broadening its scope to the design and construction fields. By fostering an innovation culture, they have created an environment where complex technology is hidden behind the platform, allowing users to focus solely on better decision-making.

The collaboration between Samsung C&T's Construction Division and Salesforce is more than just the adoption of a system; it is a journey of innovation that demonstrates the new future created by AI and data in the traditional construction industry. Their efforts to realize the vision of "Creating a Better Future" are setting a new paradigm in the global construction sector.